My car has had oil coming through the dipstick tube for many miles. I installed pcv update #6, and I would still find oil up there. Blow-by doesnt seem excessive using the rev-car-with-dipstick-out method, and compression has been great... right around 200 psi on all four at 120kmi, and about the same at 163kmi when I pulled the engine to do the timing chain and many (all?) the gaskets.

I found lots of carbon/oil on the piston tops as well, and oil throughout the pcv system when I took it out..

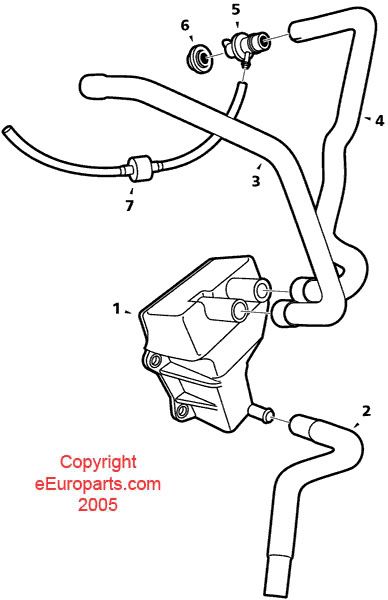

In order to keep the engine from leaking after this project, I will need to solve my crank case venting issue. No one seems to have a diagram of the whole system; even the install instructions from the kit leave questions as to which way the check valves should go.

i.e. the check valve on the tube going to the dipstick... points towards the dipstick.. seems like that should go the other way.

Has anyone run a catch can on a T7 car? Maybe that's the way to go? I'm kinda stumped here.

Thanks for the help so far on this project. Finally have 'nearly' all the parts in hand for the reassembly. Can't wait to drive her again.

I found lots of carbon/oil on the piston tops as well, and oil throughout the pcv system when I took it out..

In order to keep the engine from leaking after this project, I will need to solve my crank case venting issue. No one seems to have a diagram of the whole system; even the install instructions from the kit leave questions as to which way the check valves should go.

i.e. the check valve on the tube going to the dipstick... points towards the dipstick.. seems like that should go the other way.

Has anyone run a catch can on a T7 car? Maybe that's the way to go? I'm kinda stumped here.

Thanks for the help so far on this project. Finally have 'nearly' all the parts in hand for the reassembly. Can't wait to drive her again.