Hello -

For the past year, I have been working on improving the appearances of a 1991 9000. The exterior paint color is Cirrus White, the interior is a dark grey leather interior.

Locally, I used a young man who owns a small business, to do my powder coating work. With the economy as it is, he is having a really tough time, to the point that I have decided to buy into his company.

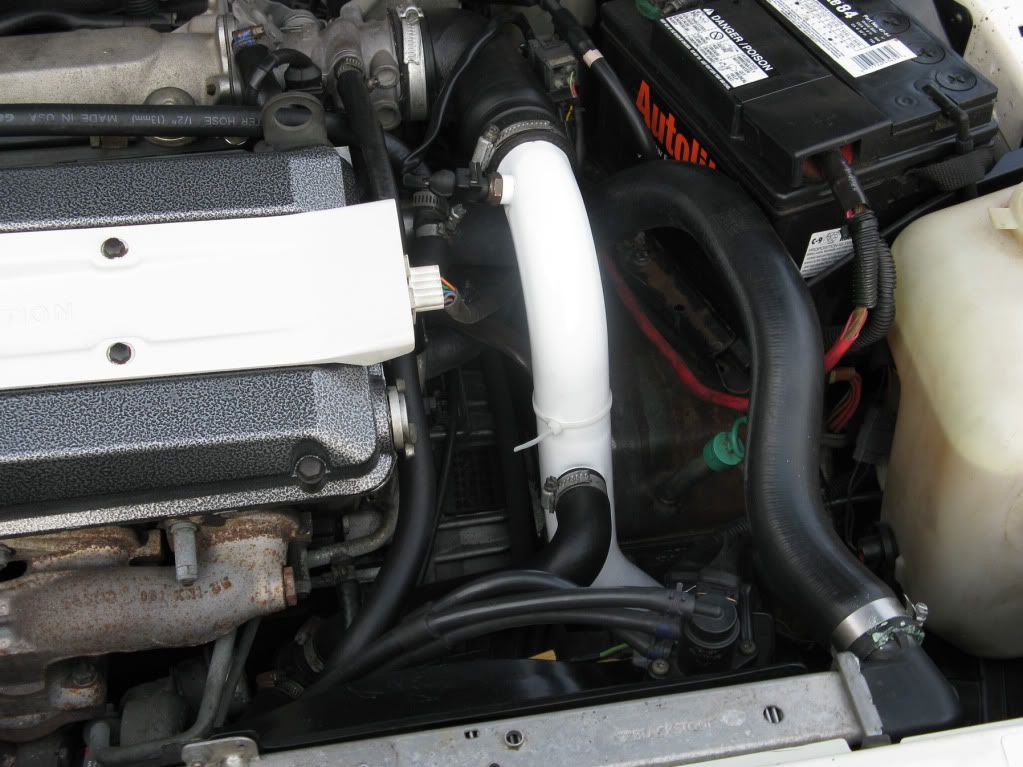

He has recently powder coated the wheels for this 9000, Cirrus White in color. The wheels were displayed in the 9000 area discussion group, so you can find photos there. He also powder coated the charge pipe in Cirrus White and coated the valve cover in Silver Vein. Some of these pieces were also in the 9000 forum group. There are several photos at the end of this text.

As a result of his high quality of workmanship, which many people saw last week at the Carlisle show. I had numerous requests by other SAABers to help them with powder coating items.

Currently, we have in stock, several valve covers - dual cam design for the model 900, 9000, 9-3 and 9-5 cars. If you want to improve the appearance of the engine bay of your car, this is a great place to begin. We can also coat your wheels, charge pipe, intake manifold, turbo heat shields and just about any other metal parts. An almost infanite variety of colors are available. We also can use the ceramic coating materials for those high heat applications, such as the turbo heat shield. Please note that the color selection is not as wide with the ceramic coatings.

Several photos are attached, please send me a PM if you have any questions or interest.

![Image]()

![Image]()

![Image]()

![Image]()

Thank you in advance for your interest. Once I settle on a business name, we shall begin to develop a web-site and establish other methods to communicate with me. I hope that I have not offended anyone by placing this thread in the For Sale area, it just seemed logical to put it here.

BTW, we can also powder coat aluminum lawn furniture, lawn ornaments such as sun-dials. Photo of one of those to follow next week, we are doing that right now. Motorcycle parts / frames and just about any other metal items.

Below are two photos of a Turbo Heat Shield for the 9-5 / 4-cyl engine. It is ceramic powder coated in a light silver - grey, two-tone finish. Top photo is of the top surface and bottom photo is of the underside of the shield.

![Image]()

![Image]()

George Kuhn

For the past year, I have been working on improving the appearances of a 1991 9000. The exterior paint color is Cirrus White, the interior is a dark grey leather interior.

Locally, I used a young man who owns a small business, to do my powder coating work. With the economy as it is, he is having a really tough time, to the point that I have decided to buy into his company.

He has recently powder coated the wheels for this 9000, Cirrus White in color. The wheels were displayed in the 9000 area discussion group, so you can find photos there. He also powder coated the charge pipe in Cirrus White and coated the valve cover in Silver Vein. Some of these pieces were also in the 9000 forum group. There are several photos at the end of this text.

As a result of his high quality of workmanship, which many people saw last week at the Carlisle show. I had numerous requests by other SAABers to help them with powder coating items.

Currently, we have in stock, several valve covers - dual cam design for the model 900, 9000, 9-3 and 9-5 cars. If you want to improve the appearance of the engine bay of your car, this is a great place to begin. We can also coat your wheels, charge pipe, intake manifold, turbo heat shields and just about any other metal parts. An almost infanite variety of colors are available. We also can use the ceramic coating materials for those high heat applications, such as the turbo heat shield. Please note that the color selection is not as wide with the ceramic coatings.

Several photos are attached, please send me a PM if you have any questions or interest.

Thank you in advance for your interest. Once I settle on a business name, we shall begin to develop a web-site and establish other methods to communicate with me. I hope that I have not offended anyone by placing this thread in the For Sale area, it just seemed logical to put it here.

BTW, we can also powder coat aluminum lawn furniture, lawn ornaments such as sun-dials. Photo of one of those to follow next week, we are doing that right now. Motorcycle parts / frames and just about any other metal items.

Below are two photos of a Turbo Heat Shield for the 9-5 / 4-cyl engine. It is ceramic powder coated in a light silver - grey, two-tone finish. Top photo is of the top surface and bottom photo is of the underside of the shield.

George Kuhn